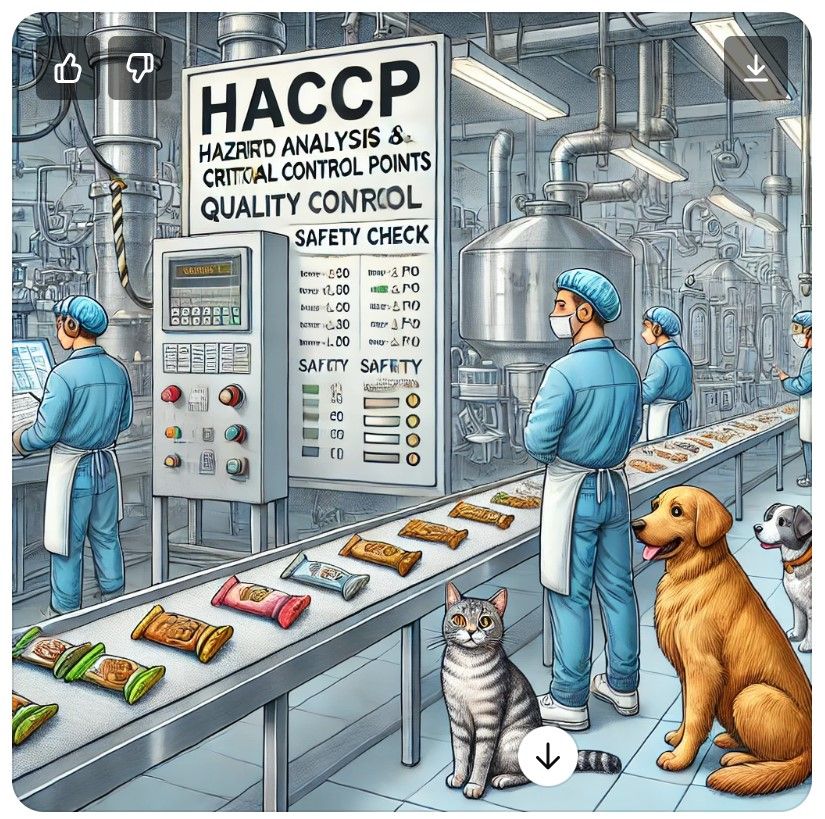

Understanding HACCP: A Practical Guide to Food Safety

The Hazard Analysis and Critical Control Points (HACCP) plan stands as a meticulous method in ensuring food safety, calling for careful consideration at each stage of production. At its core, a HACCP plan offers a framework for identifying, addressing, and managing hazards that could compromise the quality and safety of food products. More than just a set of rules, it’s a dynamic process, drawing on science and practice to safeguard the journey from farm to fork.

Breaking Down the HACCP Plan

-

Hazard Analysis

Every production process contains potential hazards—biological, chemical, or physical—that could affect the final product. Here, we map out each step to pinpoint where these risks might arise, from raw material handling to the final stages of packaging. By conducting a thorough hazard analysis, we gain a clearer understanding of where controls are essential. -

Critical Control Points (CCPs)

Critical Control Points, or CCPs, represent the junctures where intervention can prevent, eliminate, or significantly reduce a hazard. Think of them as the vital checkpoints in a process: cooking to a safe temperature, for example, or ensuring proper storage conditions. Each CCP is selected based on its power to mitigate specific risks, making it integral to keeping food safe. -

Critical Limits

To make these CCPs effective, each one must operate within predefined critical limits. These limits could be specific temperatures, pH levels, or other measurable conditions. By setting these parameters, we ensure each CCP performs as expected, maintaining a threshold that ensures safety. -

Monitoring Procedures

With the limits defined, monitoring steps in as a crucial layer of oversight. Monitoring ensures CCPs stay within their limits and calls for documentation that tracks compliance in real time. It’s a way of consistently validating that each part of the process remains controlled and safe. -

Corrective Actions

Despite careful planning, deviations can occur. When they do, corrective actions provide the necessary response to restore control. If, for example, a temperature fails to meet the critical limit, corrective measures might involve adjusting the process or re-cooking, ensuring that safety standards aren’t compromised. -

Verification Procedures

Verification isn’t just a one-time check; it’s a periodic review that confirms the entire HACCP plan functions as intended. By validating each step, we test the integrity of controls and their ability to manage risks effectively, reinforcing the safety measures that protect consumers. -

Record-Keeping and Documentation

Documentation is more than just a compliance requirement—it’s a historical record of our commitment to safety. Each hazard analysis, each CCP, each corrective action, and each verification cycle adds to the narrative of quality and transparency. Accurate records not only meet regulatory requirements but build a lasting trust with consumers and stakeholders.

The HACCP Advantage

Embracing HACCP offers a strategic advantage by emphasizing prevention over reaction. It’s not just about avoiding contamination but about ensuring consistent quality and building a foundation of trust with every step in the process. By embedding this system into food production, companies not only meet standards but can exceed them, promoting safety, efficiency, and quality in every product that reaches consumers.

Identify the Food Safety Risk in This Image: What Concerns Do You See?